Plastic welding has emerged as a cornerstone skill in various industries today, showcasing the transformative power of technology and human ingenuity. A plastic welder harnesses heat and pressure to fuse plastic materials, creating durable, seamless repairs vital for everything from automotive parts to household goods. As we hurtle into 2026, with the increasing complexity and specialization in materials, the role of the plastic welder has evolved dramatically, emphasizing sustainability and precision.

Understanding the Role of a Plastic Welder in Today’s Industry

The importance of a plastic welder can’t be overstated. This specialized skill set not only allows for the repair and assembly of a multitude of plastic components but also stands as a testimony to innovation. In modern times, as businesses grow more environmentally conscious, the demand for proficient plastic welders continues to rise. Companies across various sectors—from automotive giants like Ford, which use stringent welding techniques to manufacture car bumpers, to tech firms developing gadgets that utilize a plethora of plastic components—rely on the expertise of plastic welders.

As we embrace a world filled with disposable products, promoting repair over replacement contributes positively to our planet. The plastic welding profession fosters sustainable practices, helping reduce waste and encouraging a circular economy where resources are reused. This is especially relevant in 2026, as companies increasingly embrace sustainability as part of their brand identity.

With cutting-edge techniques constantly developing, plastic welders play a critical role in pushing the industry forward—creating solutions that blend function and aesthetics while minimizing waste. These skilled artisans don’t just put plastic pieces back together; they engineer better, smarter, and longer-lasting products.

2. Top 5 Benefits of Hiring a Skilled Plastic Welder

When considering hiring a plastic welder, the advantages extend far beyond simple repairs. Here are five core benefits that highlight the value of engaging expert talent in this field:

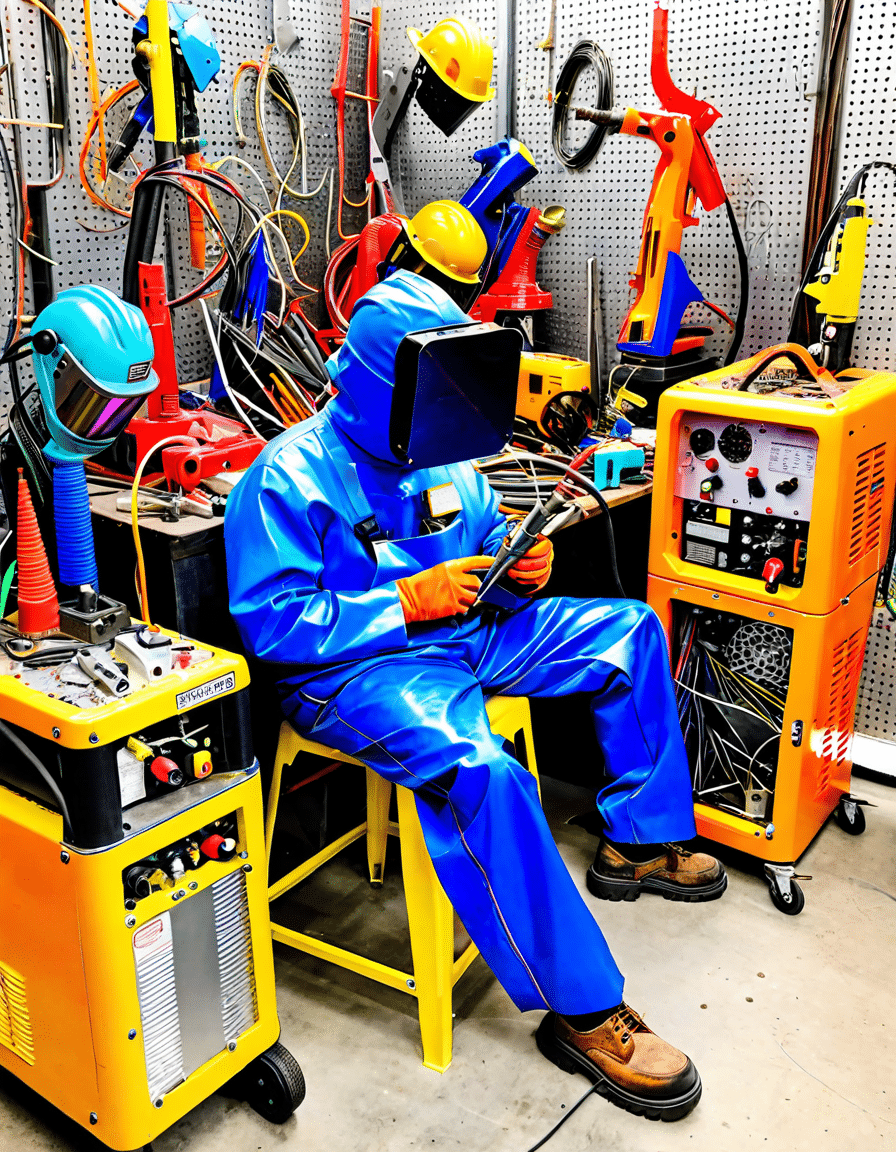

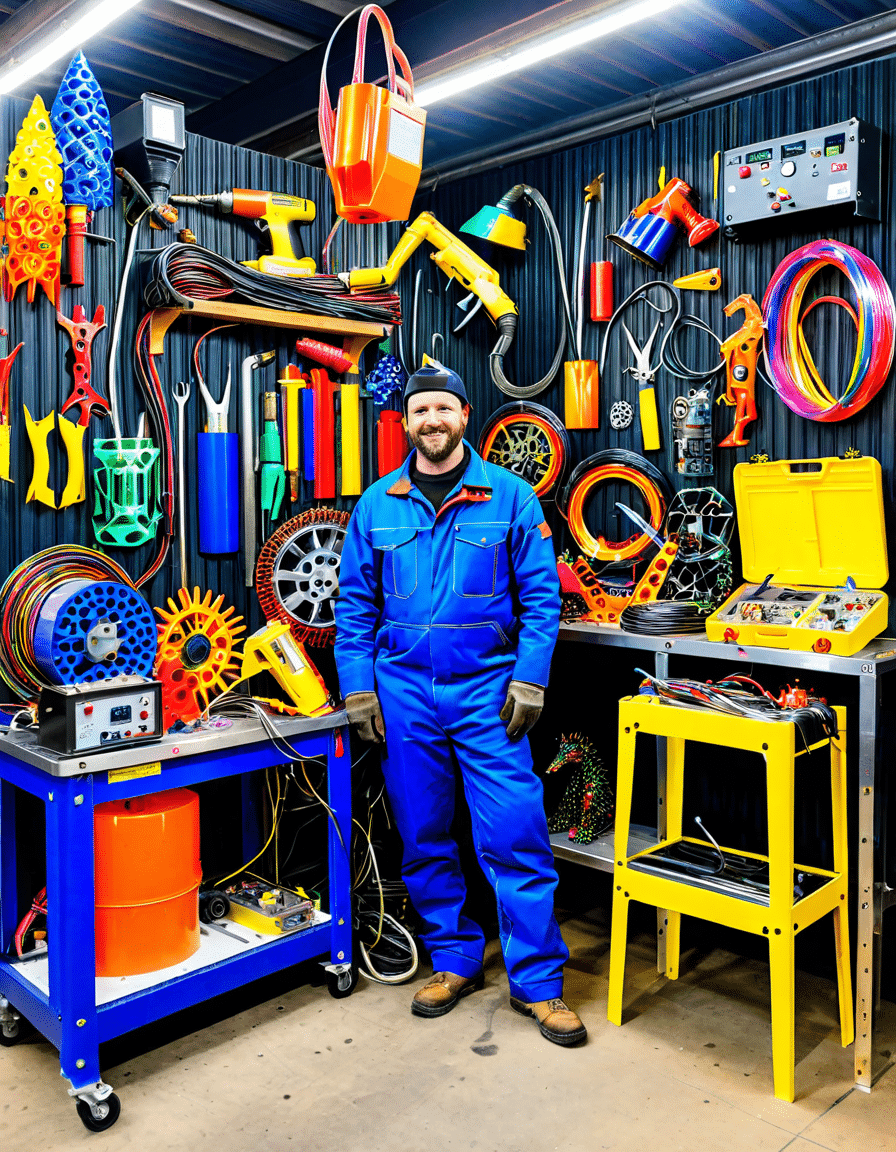

3. Tools of the Trade: Essential Equipment in Plastic Welding

To excel in plastic welding, familiarity with essential tools is crucial. Here are some of the top equipment used:

4. Mastering Techniques: The Science Behind Plastic Welding

While possessing the right tools is important, understanding the science behind welding techniques elevates a plastic welder’s craft to the next level. Let’s explore a few key methods:

Final Thoughts on the Craft of Plastic Welding

As we move through 2026, the expertise of plastic welders is more important than ever. They are not just technicians; they are craftsmen who specialize in precision repair grounded in material science. The role of a plastic welder continues to adapt to evolving technologies and practices, showcasing an unwavering commitment to sustainability and innovative solutions.

By fusing state-of-the-art tools with outstanding techniques and a deep understanding of the science involved, plastic welders consistently push the limits of what’s achievable. This craft is significant not just for the products they repair, but for shaping the future of manufacturing and resource conservation. Let’s appreciate the artistry behind their work—after all, repairing is indeed an art, and mastering it is a calling in today’s technology-driven age.

Plastic Welder: Fun Trivia and Interesting Facts

A Little History Goes a Long Way

Did you know that the art of welding has origins dating back to ancient Egypt? Just like a plastic welder today, the workers of that time used heat to fuse materials. Jumping into the modern era, plastic welding took off in the 1940s when plastics became mainstream. Now, you might think of plastically fused items as being flimsy, but they pack a punch! For instance, did you know a Usb fan can be repaired using plastic welding? This handy tool not only cools you off but can often have components fixed rather than replaced, thanks to skilled plastic welders.

Precision in Every Joint

A plastic welder’s precision mirrors an artist’s finesse. Skilled professionals, like those who practice needle Felting, work carefully to ensure every joint holds strong, much like the intricate designs of felted art. The magic lies in knowing the right temperature for the job, which can be akin to adjusting the heat of a stovetop for cooking; too hot or too cold, and you’ll get a disaster instead of a delicious dish or a solid repair! When assembling items that weigh around 57kg To Lbs, a plastic welder’s expertise plays a crucial role in keeping everything sturdy.

Beyond Repairs: The Fascination Continues

What’s truly fascinating is that plastic welding isn’t just about fixing old toys or household items—it’s also critical in industries like aerospace and automotive. Just think of how often you see a car with a dented bumper; a plastic welder works wonders here, restoring both aesthetics and safety. Speaking of numbers, if a plastic part weighs about 105kg To Lbs, it requires specialized techniques to ensure the repairs can withstand pressure and strain.

In a world bustling with innovation and creativity, you might stumble upon the occasional quirky tidbit. Have you heard about the aurora Borealis in Colorado? Much like the breathtaking beauty the northern lights provide, a plastic welder’s artistry shines through in their work, transforming the old into something usable again. So next time you see a plastic item in need of love, remember the skilled hands behind the scenes—those dedicated plastic welders masterfully crafting precision with every repair.