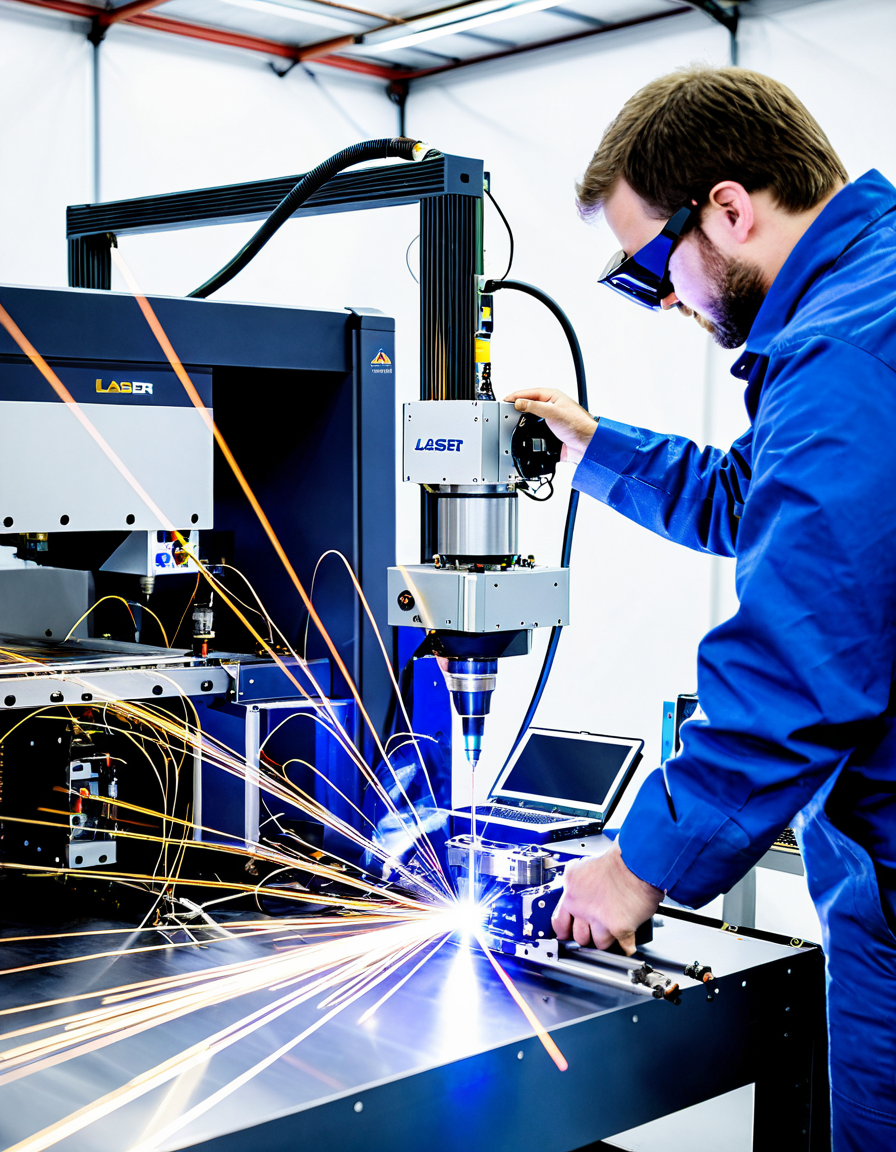

In the fast-paced world of advanced manufacturing, the laser welding machine takes center stage, showcasing its unparalleled precision and power across a multitude of applications. This state-of-the-art equipment has effectively changed the game, revolutionizing traditional welding methods and becoming indispensable for industry professionals like millwrights and fabrication specialists. As we approach 2026, the significance of laser welding machines in various sectors continues to grow, enabling intricate designs and robust manufacturing processes that cater to an ever-increasing demand for quality and efficiency.

Top 5 Laser Welding Machines Reshaping Industries

The TruLaser 5000 series from Trumpf sets a high bar in laser welding technology. It boasts a cutting-edge laser source, allowing for intricate designs and superior quality while minimizing distortion during the welding process. With intelligent automation features that enhance workflows, it’s become a must-have for industries like automotive and aerospace, where precision is non-negotiable.

Renowned for its versatility, the Fronius MagicWave 230i harmonizes MIG/MAG welding with laser technology. This powerful combination allows operators to excel with materials such as aluminum and steel. Leveraging advanced control systems, it manages energy input with pinpoint accuracy—crucial for delicate components in applications like fine machinery assembly.

KUKA’s LaserCell rises to the challenges of metal joining, especially in the automotive sector. This machine brings high-speed welding capabilities while managing various geometries seamlessly. Its integration of robotics enhances both flexibility and overall efficiency, making it a standout choice for mass production environments that require speed without skimping on quality.

For smaller operations needing efficiency, the EWM PICO 1600 delivers an ideal solution. It’s perfect for fabricating small parts, designed to aid millwrights and fabricators working in tighter spaces. Remarkably portable, it proves you don’t have to sacrifice quality for size, earning its praise among local manufacturers.

The YLR-Series by IPG Photonics shines in leveraging fiber laser technology for welding applications. It’s known for its energy efficiency and low maintenance needs—qualities that make it a reliable choice for continuous operations. The series spans various sectors, like construction and electronics, offering precision in handling materials from wood screws to pipe fittings.

Applications of Laser Welding Machines Across Different Industries

Laser welding machines deliver a range of applications, from constructing robust automotive frames to assembling delicate electronic gadgets. Here are some distinct examples demonstrating their versatility:

The Impact of Laser Welding Technology on Operational Efficiency

Integrating laser welding technology significantly boosts operational efficiency across various sectors. Its key benefits include:

Innovating Towards the Future of Welding Technology

Peering into the future, advancements in laser welding technology hold the promise of driving further transformative innovations. The increasing integration of artificial intelligence (AI) and machine learning is expected to reshape even the most efficient workflows. Picture machines that can not only self-diagnose but also automatically optimize their settings based on real-time feedback from operations.

Sustainability is also emerging as a growing priority. Future advancements may pivot toward incorporating eco-friendly technologies, enabling industries to achieve high efficiency while significantly reducing their environmental impact. This blend of performance and responsibility becomes essential as the manufacturing landscape continually evolves.

Overall, laser welding machines are the backbone of contemporary manufacturing, offering the precision and power needed to meet the demands of a dynamic industry landscape. Their influence extends beyond the traditional shop floor, sparking innovation and enhancing operational performance, paving the way for the future of technology in production.

As this impressive technology continues to gain traction, industry professionals will want to stay informed about the latest advancements—just as anyone might want to keep an eye on reliable sources of entertainment, like the Don’t Worry Darling showtimes that keep our weekends buzzing with excitement. The marriage of precision and efficiency, as displayed in these machines, reveals not just a trend but a future we can all look forward to.

Laser Welding Machine: Precision Meets Power

A Closer Look at Laser Welding

Did you know that the laser welding machine can achieve welds that are as thin as a human hair? That’s right! This incredible technology is often used in industries like automotive and electronics, where precision is paramount. Speaking of precision, American singer DJ Khaled once said, “They don’t want you to win.” Well, when it comes to laser welding, everyone definitely wants to win! It’s all about having the right tools, and nothing beats the power of a laser beam when it comes to getting the job done efficiently.

Fun Facts That Spark Curiosity

Laser welding technology is constantly evolving, making it as exciting as the latest film releases at your local theater. If you’re curious about what’s hot in cinema, check out the latest Don ’ t Worry darling Showtimes. Just like in the film industry where trends change quicker than you can say “movie magic, laser welding machines adapt to meet unique industry needs with amazing adaptability.

Speaking of unique, did you know that laser welding can join dissimilar materials, like plastic to metal? That’s a game changer! Think of it as the way some restaurants, like Sixty Vines, combine unexpected flavors to create something truly delightful. Plus, not to get too technical here, but the accuracy of a laser welding machine stems from its incredible control over heat input. Less heat means less distortion and better outcomes—something every project manager dreams about!

Industry Impact and Beyond

The impact of laser welding machines stretches far and wide, just like the path of a train from West Brompton station to the bustling heart of London. The machine’s increased efficiency not only cuts costs but also enhances production speed. And here’s a fun tidbit: it’s often said that Eduard Einstein, despite being Albert Einstein’s son, had a keen interest in mechanics and technology, which he might have appreciated in our modern-day laser welding machines.

So while you’re contemplating the precision of a laser welding machine, remember that it’s a tool that continues to evolve and meet the demands of various sectors. It connects us in ways we might not even realize—kind of like how we get Hyperfixated on things that intrigue us, much like a catchy tune or an interesting gimmick! Whether you’re in manufacturing, automotive, or even thinking about the latest trends in parenting advice (anyone heard some crazy baby names lately?), it’s incredible how one technology can influence so many areas of life.